McGraw-Hill Book Co. Inc.

PUBLISHERS OF BOOKS FOR

Coal Age ▼ Electric Railway Journal

Electrical World ▼ Engineering News-Record

American Machinist ▼ Ingeniería Internacional

Engineering & Mining Journal ▼ Power

Chemical & Metallurgical Engineering

Electrical Merchandising

CHEMICAL WARFARE

BY

AMOS A. FRIES

Brigadier General, C. W. S., U. S. A.

Chief, Chemical Warfare Service

AND

CLARENCE J. WEST

Major, C. W. S. Reserve Corps, U. S. A.

National Research Council

First Edition

McGRAW-HILL BOOK COMPANY, Inc.

NEW YORK: 370 SEVENTH AVENUE

LONDON: 6 & 8 BOUVERIE ST., E. C. 4

1921

Copyright, 1921, by the

McGraw-Hill Book Company, Inc.

[Pg vii]

Shortly after the signing of the Armistice, it was realized that the story of Chemical Warfare should be written, partly because of its historical value, and partly because of the future needs of a textbook covering the fundamental facts of the Service for the Army, the Reserve Officer, the National Guard, and even the Civilian Chemist. The present work was undertaken by both authors as a labor of patriotism and because of their interest in the Service.

The two years which have elapsed since the initial discussion of the outlines of the book have thoroughly convinced us of the need of such a work. The Engineers, the Medical Department, and most of the other branches of the Army have their recognized textbooks and manuals. There has been no way, however, by which the uninformed can check the accuracy of statements regarding Chemical Warfare. The present volume will serve, in a measure, to fill this gap. That it does not do so more completely is due in part to the fact that secrecy must still be maintained about some of the facts and some of the new discoveries which are the property of the Service. Those familiar with the work of the Chemical Warfare Service will discover, though, that the following pages contain many statements which were zealously guarded secrets two years ago. This enlarged program of publicity on the part of the Chief of the Service is being justified every day by the ever increasing interest in this branch of warfare. Where five men were discussing Chemical Warfare two years ago, fifty men are talking about the work and the possibilities of the Service today. It is hoped that the facts here presented may further increase the interest in Chemical Warfare, for there is no question but that it must be recognized as a permanent and a very vital branch of the Army of every country. Reasons for this will be found scattered through the pages of this book. [Pg viii]

It should be explained that this is in no sense a complete historical sketch of the development and personnel of the Chemical Warfare Service. At least two more volumes are needed,—one on the Manufacture of Poisonous Gases and one on the Tactics of Chemical Warfare. We have purposely refrained from an attempt to give credit to individuals for the accomplishments of the various Divisions of the Service, because such an attempt would have made the book too voluminous, and would have defeated the primary purpose, namely, that it should present the information in as concise manner as possible. The published and unpublished materials of the files of all the Divisions have been freely drawn upon in writing the various chapters, and many old C. W. S. men will undoubtedly recognize whole sentences which they wrote under the stress of the laboratory or plant “battle front.” May these few lines be an acknowledgment of their contributions. Those who desire to consult the literature of Chemical Warfare will find a fairly complete bibliography (to about the middle of 1919) in “Special Libraries” for November, 1919.

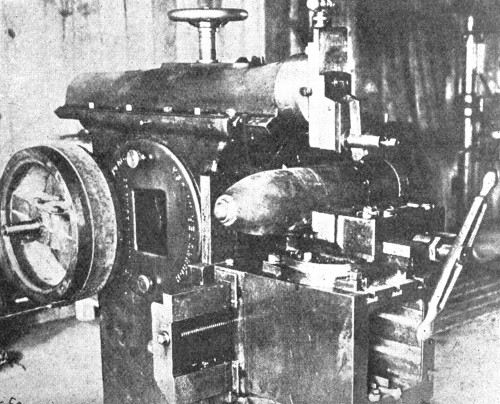

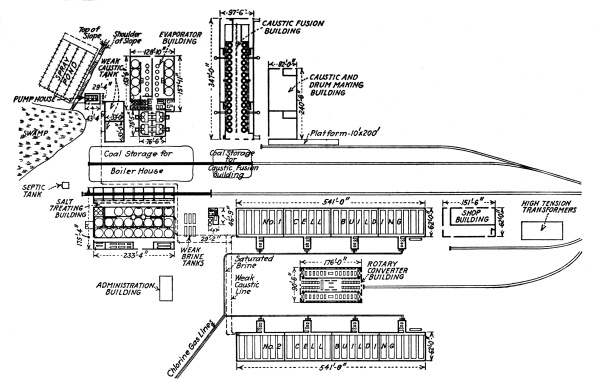

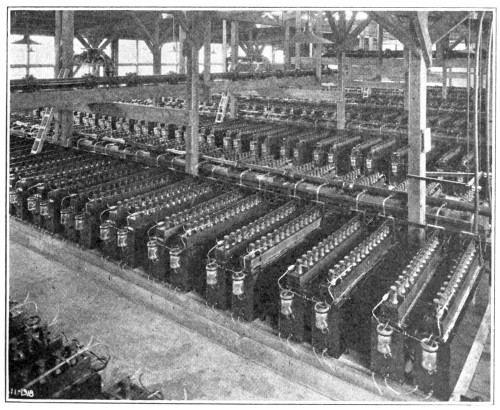

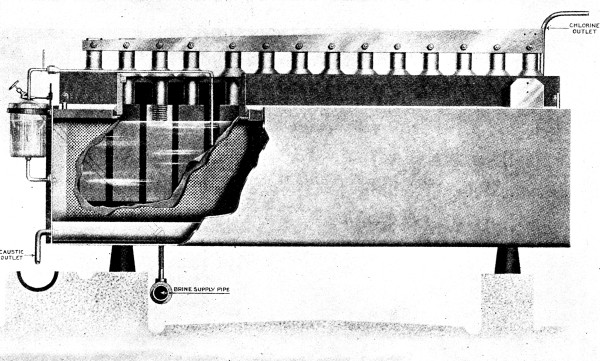

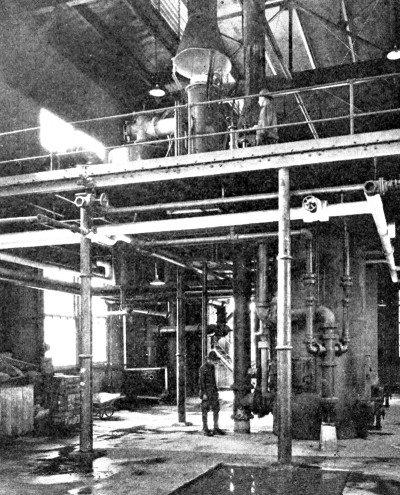

Special acknowledgment is made to Dr. G. J. Esselen, Jr., for having read the manuscript and for helpful and constructive criticisms. Many of the figures are reproduced by permission of the Journal of Industrial and Engineering Chemistry; those showing the Nelson cell were furnished by the Samuel M. Green Company.

Aug. 1, 1921.

[Pg ix]

After all peaceful means of settling disputes between nations have been resorted to and have failed, war is often declared by one of the disputants for the purpose of imposing its will upon the other by force. In order to accomplish this, a superiority must be established over the adversary in trained men and in implements of war.

Men are nothing in modern war unless they are equipped with the most effective devices for killing and maiming the enemy’s soldiers and thoroughly trained in the use of such implements.

History proves that an effective implement of war has never been discarded until it becomes obsolete.

It is impossible to humanize the act of killing and maiming the enemy’s soldiers, and there is no logical grounds on which to condemn an appliance so long as its application can be so confined. Experiments in this and other countries during the World War completely established the fact that gas can be so confined. The range of gas clouds is no greater than that of artillery and the population in the area behind the front line must, if they remain in such range, take their chance. The danger area in the future will be known to all.

As the first Director of the Chemical Warfare Service, U. S. Army, I speak with some experience when I say that there is no field in which the future possibilities are greater than in chemical warfare, and no field in which neglect to keep abreast of the times in research and training would be more disastrous.

Notwithstanding the fact that gas was used in the World War two years before the United States entered the fray, practically nothing was done in this country before April, 1917, towards the development of any chemical warfare appliances, offensive or defensive, and had it not been for the ability of an ally to supply our troops with such [Pg x] appliances, they would have been as defenseless as the Canadians were at Ypres when the Germans sent over their first gas cloud.

This book recites the troubles and successes of this new service under the stress of war for which it was unprepared and I trust that its perusal will create a public opinion that will insist upon chemical preparation for war.

I feel that this book will show that the genius and patriotism displayed by the chemists and chemical engineers of the country were not surpassed in any other branch of war work and that to fail to utilize in peace times this talent would be a crime.

[Pg xi]

CONTENTS

| PAGE | ||

| Preface | vii | |

| Foreword | ix | |

| chapter | ||

| I. | The History of Poison Gases | 1 |

| II. | Modern Development of Gas Warfare | 10 |

| III. | Development of the | |

| Chemical Warfare Service | 31 | |

| IV. | The Chemical Warfare Service in France | 72 |

| V. | Chlorine | 116 |

| VI. | Phosgene | 126 |

| VII. | Lachrymators | 137 |

| VIII. | Chloropicrin | 144 |

| IX. | Dichloroethylsulfide (Mustard Gas) | 150 |

| X. | Arsenic Derivatives | 180 |

| XI. | Carbon Monoxide | 190 |

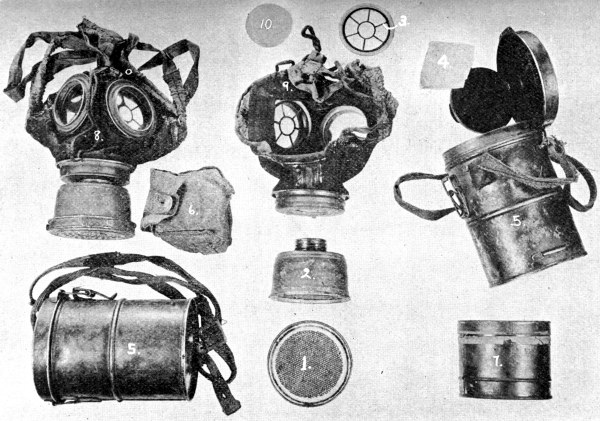

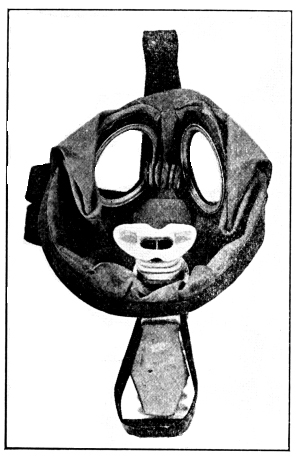

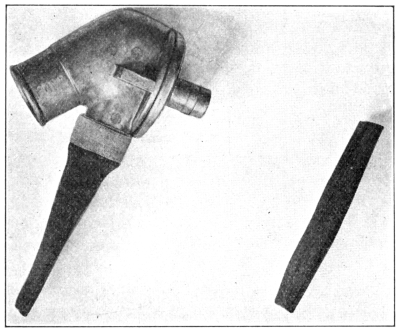

| XII. | Development of the Gas Mask | 195 |

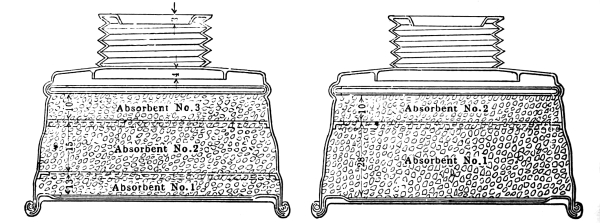

| XIII. | Absorbents | 237 |

| XIV. | Testing Absorbents and Gas Masks | 259 |

| XV. | Other Defensive Measures | 272 |

| XVI. | Screening Smokes | 285 |

| XVII. | Toxic Smokes | 313 |

| XVIII. | Smoke Filters | 322 |

| XIX. | Signal Smokes | 330 |

| XX. | Incendiary Materials | 336 |

| XXI. | The Pharmacology of War Gases | 353 |

| XXII. | Chemical Warfare in Relation to | |

| Strategy and Tactics | 363 | |

| XXIII. | The Offensive Use of Gas | 385 |

| XXIV. | Defense against Gas | 405 |

| XXV. | Peace Time Uses of Gas | 427 |

| XXVI. | The Future of Chemical Warfare | 435 |

| Index | 440 | |

[Pg 1]

CHEMICAL WARFARE

The introduction of poison gases by the Germans at Ypres in April, 1915, marked a new era in modern warfare. The popular opinion is that this form of warfare was original with the Germans. Such, however, is not the case. Quoting from an article in the Candid Quarterly Review, 4, 561, “All they can claim is the inhuman adoption of devices invented in England, and by England rejected as too horrible to be entertained even for use against an enemy.” But the use of poison gases is even of an earlier origin than this article claims.

The first recorded effort to overcome an enemy by the generation of poisonous and suffocating gases seems to have been in the wars of the Athenians and Spartans (431-404 b.c.) when, besieging the cities of Platea and Belium, the Spartans saturated wood with pitch and sulfur and burned it under the walls of these cities in the hope of choking the defenders and rendering the assault less difficult. Similar uses of poisonous gases are recorded during the Middle Ages. In effect they were like our modern stink balls, but were projected by squirts or in bottles after the manner of a hand grenade. The legend is told of Prester John (about the eleventh century), that he stuffed copper figures with explosives and combustible materials which, emitted from the mouths and nostrils of the effigies, played great havoc.

The idea referred to by the writer in the Candid Quarterly Review, is from the pen of the English Lord Dundonald, which [Pg 2] appeared in the publication entitled “The Panmure Papers.” This is an extremely dull record of an extremely dull person, only rendered interesting by the one portion, concerned with the use of poison gases, which, it is said, “should never have been published at all.”

That portion of the article from the Candid Quarterly Review dealing with the introduction of poisonous gas by the Germans, and referred to in the first paragraph above, is quoted in full as follows:

“The great Admiral Lord Dundonald—perhaps the ablest sea captain ever known, not even excluding Lord Nelson—was also a man of wide observation, and no mean chemist. He had been struck in 1811 by the deadly character of the fumes of sulphur in Sicily; and, when the Crimean War was being waged, he communicated to the English government, then presided over by Lord Palmerston, a plan for the reduction of Sebastopol by sulphur fumes. The plan was imparted to Lord Panmure and Lord Palmerston, and the way in which it was received is so illustrative of the trickery and treachery of the politician that it is worth while to quote Lord Palmerston’s private communication upon it to Lord Panmure:

“Lord Palmerston to Lord Panmure

“‘House of Commons, 7th August, 1855 “‘I agree with you that if Dundonald will go out himself to superintend and direct the execution of his scheme, we ought to accept his offer and try his plan. If it succeeds, it will, as you say, save a great number of English and French lives; if it fails in his hands, we shall be exempt from blame, and if we come in for a small share of the ridicule, we can bear it, and the greater part will fall on him. You had best, therefore, make arrangement with him without delay, and with as much secrecy as the nature of things will admit of.’

“Inasmuch as Lord Dundonald’s plans have already been deliberately published by the two persons above named, there can be no harm in now republishing them. They will be found in the first volume of ‘The Panmure Papers’ (pp. 340-342) and are as follows:

[Pg 3]

“‘(Enclosure)

“‘Brief Preliminary Observations

“‘It was observed when viewing the Sulphur Kilns, in July, 1811, that the fumes which escaped in the rude process of extracting the material, though first elevated by heat, soon fell to the ground, destroying all vegetation, and endangering animal life to a great distance, and it was asserted that an ordinance existed prohibiting persons from sleeping within the distance of three miles during the melting season.

“‘An application of these facts was immediately made to Military and Naval purposes, and after mature consideration, a Memorial was presented on the subject to His Royal Highness the Prince Regent on the 12th of April, 1812, who was graciously pleased to lay it before a Commission, consisting of Lord Keith, Lord Exmouth and General and Colonel Congreve (afterwards Sir William), by whom a favorable report having been given, His Royal Highness was pleased to order that secrecy should be maintained by all parties.

“‘7th August, 1855’

“‘Memorandum

“‘Materials required for the expulsion of the Russians from Sebastopol: Experimental trials have shown that about five parts of coke effectually vaporize one part of sulphur. Mixtures for land service, where weight is of importance, may, however, probably be suggested by Professor Faraday, as to operations on shore I have paid little attention. Four or five hundred tons of sulphur and two thousand tons of coke would be sufficient.

“‘Besides these materials, it would be necessary to have, say, as much bituminous coal, and a couple of thousand barrels of gas or other tar, for the purpose of masking fortifications to be attacked, or others that flank the assailing positions.

“‘A quantity of dry firewood, chips, shavings, straw, hay or other such combustible materials, would also be requisite quickly to kindle the fires, which ought to be kept in readiness for the first favourable and steady breeze.

“‘7th August, 1855’

[Pg 4]

“‘Note.—The objects to be accomplished being specially stated the responsibility of their accomplishment ought to rest on those who direct their execution.

“‘Suppose that the Malakoff and Redan are the objects to be assailed it might be judicious merely to obscure the Redan (by the smoke of coal and tar kindled in ‘The Quarries’), so that it could not annoy the Mamelon, where the sulphur fire would be placed to expel the garrison from the Malakoff, which ought to have all the cannon that can be turned towards its ramparts employed in overthrowing its undefended ramparts.

“‘There is no doubt but that the fumes will envelop all the defenses from the Malakoff to the Barracks, and even to the line of battleship, the Twelve Apostles, at anchor in the harbour.

“‘The two outer batteries, on each side of the Port, ought to be smoked, sulphured, and blown down by explosion vessels, and their destruction completed by a few ships of war anchored under cover of the smoke.’

“That was Lord Dundonald’s plan in 1855, improperly published in 1908, and by the Germans, who thus learnt it, ruthlessly put into practise in 1915.

“Lord Dundonald’s memoranda, together with further elucidatory notes, were submitted by the English government of that day to a committee and subsequently to another committee in which Lord Playfair took leading part. These committees, with Lord Dundonald’s plans fully and in detail before them, both reported that the plans were perfectly feasible; that the effects expected from them would undoubtedly be produced; but that those effects were so horrible that no honorable combatant could use the means required to produce them. The committee therefore recommended that the scheme should not be adopted; that Lord Dundonald’s account of it should be destroyed. How the records were obtained and preserved by those who so improperly published them in 1908 we do not know. Presumably they were found among Lord Panmure’s papers. Admiral Lord Dundonald himself was certainly no party to their publication.”

One of the early, if not the earliest suggestion as to the use of poison gas in shell is found in an article on “Greek Fire,” by B. W. Richardson.[2] He says:[Pg 5]

“I feel it a duty to state openly and boldly, that if science were to be allowed her full swing, if society would really allow that ‘all is fair in war,’ war might be banished at once from the earth as a game which neither subject nor king dare play at. Globes that could distribute liquid fire could distribute also lethal agents, within the breath of which no man, however puissant, could stand and live. From the summit of Primrose Hill, a few hundred engineers, properly prepared, could render Regent’s Park, in an incredibly short space of time, utterly uninhabitable; or could make an army of men, that should even fill that space, fall with their arms in their hands, prostrate and helpless as the host of Sennacherib.

“The question is, shall these things be? I do not see that humanity should revolt, for would it not be better to destroy a host in Regent’s Park by making the men fall as in a mystical sleep, than to let down on them another host to break their bones, tear their limbs asunder and gouge out their entrails with three-cornered pikes; leaving a vast majority undead, and writhing for hours in torments of the damned? I conceive, for one, that science would be blessed in spreading her wings on the blast, and breathing into the face of a desperate horde of men prolonged sleep—for it need not necessarily be a death—which they could not grapple with, and which would yield them up with their implements of murder to an enemy that in the immensity of its power could afford to be merciful as Heaven.

“The question is, shall these things be? I think they must be. By what compact can they be stopped? It were improbable that any congress of nations could agree on any code regulating means of destruction; but if it did, it were useless; for science becomes more powerful as she concentrates her forces in the hands of units, so that a nation could only act, by the absolute and individual assent of each of her representatives. Assume, then, that France shall lay war to England, and by superior force of men should place immense hosts, well armed, on English soil. Is it probable that the units would rest in peace and allow sheer brute force to win its way to empire? Or put English troops on French soil, and reverse the question?

“To conclude. War has, at this moment, reached, in its details, such an extravagance of horror and cruelty, that it can not be made worse by any art, and can only be made more merciful by being rendered more terribly energetic. Who that had to die from a blow would not rather place his head under Nasmyth’s hammer, than submit it to a drummer-boy armed with a ferrule?”

The Army and Navy Register of May 29, 1915, reports that [Pg 6]

“among the recommendations forwarded to the Board of Ordnance and Fortifications there may be found many suggestions in favor of the asphyxiation process, mostly by the employment of gases contained in bombs to be thrown within the lines of the foe, with varying effects from peaceful slumber to instant death. One ingenious person suggested a bomb laden to its full capacity with snuff, which should be so evenly and thoroughly distributed that the enemy would be convulsed with sneezing, and in this period of paroxysm it would be possible to creep up on him and capture him in the throes of the convulsion.”

That the probable use of poisonous gas has often been in the minds of military men during recent times is evidenced by the fact that at the Hague Conference in 1899 several of the more prominent nations of Europe and Asia pledged themselves not to use projectiles whose only object was to give out suffocating or poisonous gases. Many of the Powers did not sign this declaration until later. Germany signed and ratified it on Sept. 4, 1900, but the United States never signed it. Further, this declaration was not to be binding in case of a war in which a non-signatory was or became a belligerent. Admiral Mahan, a United States delegate, stated his position in regard to the use of gas in shell (at that time an untried theory) as follows:

“The reproach of cruelty and perfidy addressed against these supposed shells was equally uttered previously against fire-arms and torpedoes, although both are now employed without scruple. It is illogical and not demonstrably humane to be tender about asphyxiating men with gas, when all are prepared to admit that it is allowable to blow the bottom out of an ironclad at midnight, throwing four or five hundred men into the sea to be choked by the water, with scarcely the remotest chance to escape.”

At the Hague Congress of 1907, article 23 of the rules adopted for war on land states:

“It is expressly forbidden (a), to employ poisons or poisonous weapons.”

Before the War suffocating cartridges were shot from the cartridge-throwing rifle of 26 mm. These cartridges were charged with ethyl bromoacetate, a slightly suffocating and non-toxic lachrymator. They were intended for attack on the flanking works of permanent fortifications, flanking casements or caponiers, into which the enemy [Pg 7] tried to make the cartridges penetrate through the narrow slits used for loopholes. The men who were serving the machine guns or the cannon of the flanking works would have been bothered by the vapor from the ethyl bromoacetate, and the assailant would have profited by their disturbance to get past the obstacle presented by the fortification. The employment of these devices, not entailing death, did not contravene the Hague conventions.

The only memorable operations in the course of which these devices were used before the War was the attack on the Bonnet gang at Choisy-le-roi.

In connection with the suggested use of sulfur dioxide by Lord Dundonald and the proposed use of poisonous gases in shell, the following description of a charcoal respirator by Dr. J. Stenhouse,[3] communicated by Dr. George Wilson in 1854, is of interest.

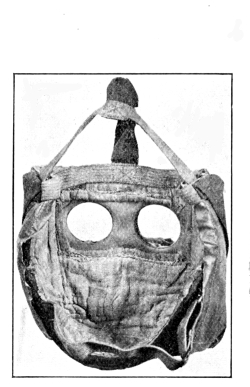

“Dr. Wilson commenced by stating that, having read with much interest the account of Dr. Stenhouse’s researches on the deodorizing and disinfecting properties of charcoal, and the application of these to the construction of a new and important kind of respirator, he had requested the accomplished chemist to send one of his instruments for exhibition to the society, which he had kindly done. Two of the instruments were now on the table, differing, however, so slightly in construction, that it would be sufficient to explain the arrangement of one of them. Externally, it had the appearance of a small fencing-mask of wire gauze, covering the face from the chin upwards to the bridge of the nose, but leaving the eyes and forehead free. It consisted, essentially, of two plates of wire gauze, separated from each other by a space of about one-fourth or one-eighth of an inch, so as to form a small cage filled with small fragments of charcoal. The frame of the cage was of copper, but the edges were made of soft lead, and were lined with velvet, so as to admit of their being made to fit the cheeks tightly and inclose the mouth and nostrils. By this arrangement, no air could enter the lungs without passing through the wire gauze and traversing the charcoal. An aperture is provided with a screw or sliding valve for the removal and replenishment of the contents of the cage, which consist of the siftings or riddlings of the lighter kinds of wood charcoal. The apparatus is attached to the face by an elastic [Pg 8] band passing over the crown of the head and strings tying behind, as in the case of the ordinary respirator. The important agent in this instrument is the charcoal, which has so remarkable a power of absorbing and destroying irritating and otherwise irrespirable and poisonous gases or vapors that, armed with the respirator, spirits of hartshorn, sulphuretted hydrogen, hydrosulphuret of ammonia and chlorine may be breathed through it with impunity, though but slightly diluted with air. This result, first obtained by Dr. Stenhouse, has been verified by those who have repeated the trial, among others by Dr. Wilson, who has tried the vapors named above on himself and four of his pupils, who have breathed them with impunity. The explanation of this remarkable property of charcoal is two-fold. It has long been known to possess the power of condensing into its pores gases and vapors, so that if freshly prepared and exposed to these, it absorbs and retains them. But it has scarcely been suspected till recently, when Dr. Stenhouse pointed out the fact, that if charcoal be allowed to absorb simultaneously such gases as sulphuretted hydrogen and air, the oxygen of this absorbed and condensed air rapidly oxidizes and destroys the accompanying gas. So marked is this action, that if dead animals be imbedded in a layer of charcoal a few inches deep, instead of being prevented from decaying as it has hitherto been supposed that they would be by the supposed antiseptic powers of the charcoal, they are found by Dr. Stenhouse to decay much faster, whilst at the same time, no offensive effluvia are evolved. The deodorizing powers of charcoal are thus established in a way they never have been before; but at the same time it is shown that the addition of charcoal to sewage refuse lessens its agricultural value contemporaneously with the lessening of odor. From these observations, which have been fully verified, it appears that by strewing charcoal coarsely powdered to the extent of a few inches, over church-yards, or by placing it inside the coffins of the dead, the escape of noisome and poisonous exhalations may be totally prevented. The charcoal respirator embodies this important discovery. It is certain that many of the miasma, malaria and infectious matters which propagate disease in the human subjects, enter the body by the lungs, and impregnating the blood there, are carried with it throughout the entire body, which they thus poison. These miasma are either gases and vapors or bodies which, like fine light dust, are readily carried through the air; moreover, they are readily destroyed by oxidizing agents, which convert them into harmless, or at least non-poisonous substances, such as water, carbonic acid and nitrogen. There is every reason, therefore, for believing that charcoal will oxidize and destroy such miasma as effectually as it does [Pg 9] sulphuretted hydrogen or hydrosulphuret of ammonia, and thus prevent their reaching and poisoning the blood. The intention accordingly is that those who are exposed to noxious vapors, or compelled to breathe infected atmospheres, shall wear the charcoal respirator, with a view to arrest and destroy the volatile poisons contained in these. Some of the non-obvious applications of the respirator were then referred to:

“1. Certain of the large chemical manufacturers in London are now supplying their workmen with the charcoal respirators as a protection against the more irritating vapors to which they are exposed.

“2. Many deaths have occurred among those employed to explore the large drains and sewers of London from exposure to sulphuretted hydrogen, etc. It may be asserted with confidence that fatal results from exposure to the drainage gases will cease as soon as the respirator is brought into use.

“3. In districts such as the Campagna of Rome, where malaria prevails and to travel during night or to sleep in which is certainly followed by an attack of dangerous and often fatal ague, the wearing of the respirator even for a few hours may be expected to render the marsh poison harmless.

“4. Those, who as clergymen, physicians or legal advisers, have to attend the sick-beds of sufferers from infectious disorders, may, on occasion, avail themselves of the protection afforded by Dr. Stenhouse’s instrument during their intercourse with the sick.

“5. The longing for a short and decisive war has led to the invention of ‘a suffocating bombshell,’ which on bursting, spreads far and wide an irrespirable or poisonous vapor; one of the liquids proposed for the shell is the strongest ammonia, and against this it is believed that the charcoal respirator may defend our soldiers. As likely to serve this end, it is at present before the Board of Ordnance.

“Dr. Wilson stated, in conclusion, that Dr. Stenhouse had no interest but a scientific one in the success of the respirators. He had declined to patent them, and desired only to apply his remarkable discoveries to the abatement of disease and death. Charcoal had long been used in filters to render poisonous water wholesome; it was now to be employed to filter poisonous air.”

[Pg 10]

The use of toxic gas in the World War dates from April 22, 1915, when the Germans launched the first cylinder attack, employing chlorine, a common and well known gas. Judging from the later experience of the Allies in perfecting this form of attack, it is probable that plans for this attack had been under way for months before it was launched. The suggestion that poisonous gases be used in warfare has been laid upon Prof. Nernst of the University of Berlin (Auld, “Gas and Flame,” page 15), while the actual field operations were said to have been under the direction of Prof. Haber of the Kaiser Wilhelm Physical Chemical Institute of Berlin. Some writers have felt that the question of preparation had been a matter of years rather than of months, and refer to the work on industrial gases as a proof of their statement. The fact that the gas attack was not more successful, that the results to be obtained were not more appreciated, and that better preparation against retaliation had not been made, argues against this idea of a long period of preparation, except possibly in a very desultory way. That such was the case is most fortunate for the allied cause, for had the German high command known the real situation at the close of the first gas attack, or had that attack been more severe, the outcome of the war of 1914 would have been very different, and the end very much earlier.

The first suggestion of a gas attack came to the British Army through the story of a German deserter. He stated that the German Army was planning to poison their enemy with a cloud of gas, and that the [Pg 11] cylinders had already been installed in the trenches. No one listened to the story, because, first of all, the whole procedure seemed so impossible and also because, in spite of the numerous examples of German barbarity, the English did not believe the Germans capable of such a violation of the Hague rules of warfare. The story appeared in the summary of information from headquarters (“Comic Cuts”) and as Auld says “was passed for information for what it is worth.” But the story was true, and on the afternoon of the 22nd of April, all the conditions being ideal, the beginning of “gas warfare” was launched. Details of that first gas attack will always be meager, for the simple reason that the men who could have told about it all lie in Flanders field where the poppies grow.

The place selected was in the northeast part of the Ypres salient, at that part of the line where the French and British lines met, running southward from where the trenches left the canal near Boesinghe. The French right was held by the —— Regiment of Turcos, while on the British left were the Canadians. Auld describes the attack as follows:

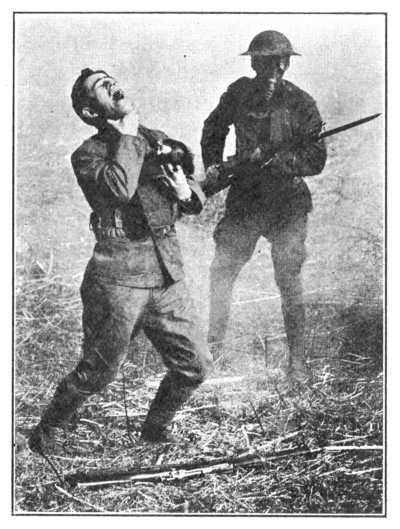

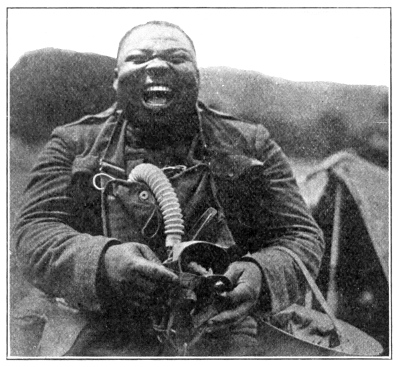

“Try to imagine the feelings and the condition of the colored troops as they saw the vast cloud of greenish-yellow gas spring out of the ground and slowly move down wind towards them, the vapor clinging to the earth, seeking out every hole and hollow and filling the trenches and shell holes as it came. First wonder, then fear; then, as the first, fringes of the cloud enveloped them and left them choking and agonized in the fight for breath—panic. Those who could move broke and ran, trying, generally in vain, to outstrip the cloud which followed inexorably after them.”

It is only to be expected that the first feeling connected with gas warfare was one of horror. That side of it is very thrillingly described by Rev. O. S. Watkins in the Methodist Recorder (London). After describing the bombardment of the City of Ypres from April 20th to 22nd he relates that in the midst of the uproar came the poison gas! [Pg 12]

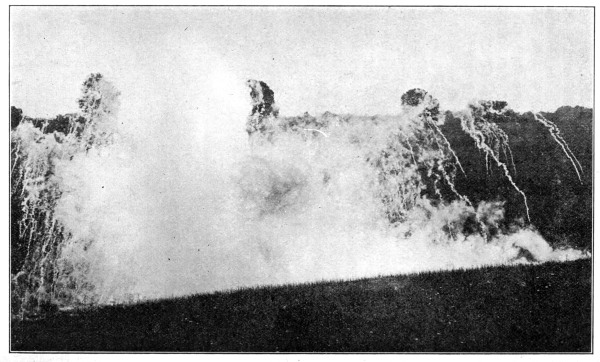

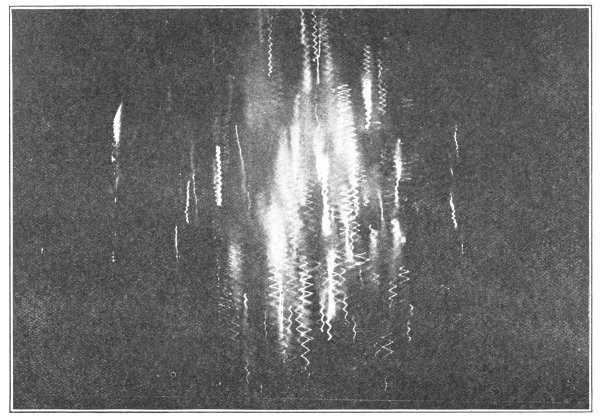

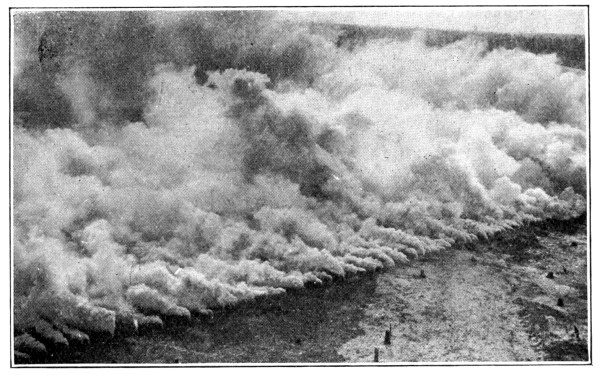

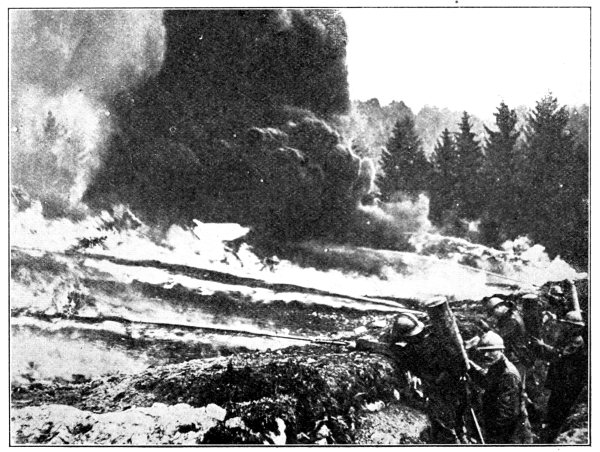

Fig. 1.—French Gas Attack as seen from an Aeroplane.

The French front, second and third line trenches are plainly visible.

The gas is seen issuing over a wide front from the front line and

drifting towards the German lines.

[Pg 13]

“Going into the open air for a few moments’ relief from the stifling atmosphere of the wards, our attention was attracted by very heavy firing to the north, where the line was held by the French. Evidently a hot fight—and eagerly we scanned the country with our field glasses hoping to glean some knowledge of the progress of the battle. Then we saw that which almost caused our hearts to stop beating—figures running wildly and in confusion over the fields.

“‘The French have broken,’ we exclaimed. We hardly believed our words.... The story they told we could not believe; we put it down to their terror-stricken imaginings—a greenish-gray cloud had swept down upon them, turning yellow as it traveled over the country, blasting everything it touched, shriveling up the vegetation. No human courage could face such a peril.

“Then there staggered into our midst French soldiers, blinded, coughing, chests heaving, faces an ugly purple color—lips speechless with agony, and behind them, in the gas-choked trenches, we learned that they had left hundreds of dead and dying comrades. The impossible was only too true.

“It was the most fiendish, wicked thing I have ever seen.”

It must be said here, however, that this was true only because the French had no protection against the gas. Indeed, it is far from being the most horrible form of warfare, provided both sides are prepared defensively and offensively. Medical records show that out of every 100 Americans gassed less than two died, and as far as records of four years show, very few are permanently injured. Out of every 100 American casualties from all forms of warfare other than gas more than 25 per cent died, while from 2 to 5 per cent more are maimed, blinded or disfigured for life. Various forms of gas, as will be shown in the following pages, make life miserable or vision impossible to those without a mask. Yet they do not kill.

Thus instead of gas warfare being the most horrible, it is the most humane where both sides are prepared for it, while against savage or unprepared peoples it can be made so humane that but very few casualties will result.

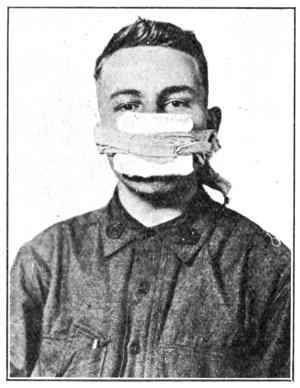

The development of methods of defense against gas will be discussed in a later chapter. It will suffice to say here that, in response to an appeal from Lord Kitchener, a temporary protection was quickly furnished the men. This was known as the “Black Veiling” respirator, and consisted of a cotton pad soaked in ordinary washing soda solution, and later, in a mixture of washing soda and “hypo,” to which was added [Pg 14] a little glycerine. These furnished a fair degree of protection to the men against chlorine, the only gas used in the early attacks.

The use of chlorine alone continued until the introduction on December 19, 1915, of a mixture of phosgene with the chlorine. This mixture offered many advantages over the use of chlorine alone (see Chapter VI).

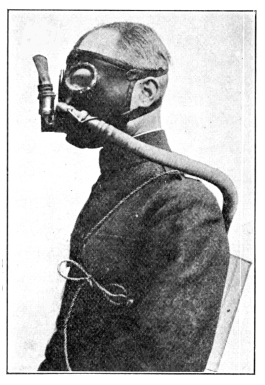

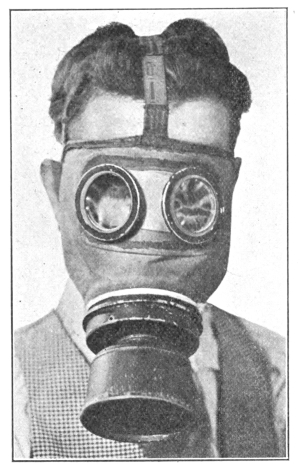

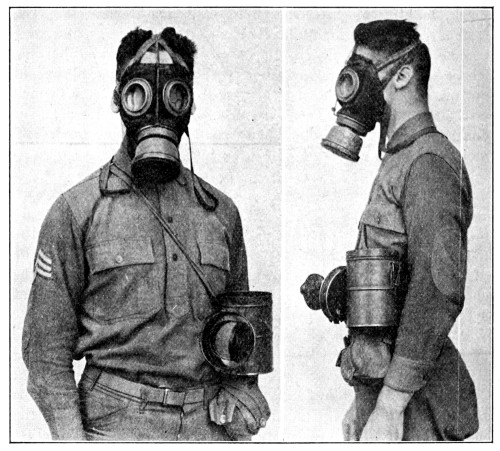

The Allies were able, through warning of the impending use of phosgene, to furnish a means of protection against it. It was at this time that the P and the PH helmets were devised, the cotton filling being impregnated with sodium phenolate and later with a mixture of sodium phenolate and hexamethylenetetramine. This helmet was used until the Standard Box Respirator was developed by the late Lt. Col. Harrison.

For a week or two the Allies were very hesitant about adopting gas warfare. However, when the repeated use of gas by the Germans made it evident that, in spite of what the Hague had to say about the matter, gas was to be a part, and as later developments showed, a very important part of modern warfare, they realized there was no choice on their part and that they had to retaliate in like manner. This decision was reached in May of 1915. It was followed by the organization of a Gas Service and intensive work on the part of chemists, engineers and physiologists. It was September 25, 1915, however, before the English were in a position to render a gas attack. From then on the Service grew in numbers and in importance, whether viewed from the standpoint of research, production, or field operations.

The Allies of course adopted not only chlorine but phosgene as well, since both were cheap, easy of preparation and effective. They felt during the early part of the War that they should adopt a substance that would kill instantly, and not one that would cause men to suffer either during the attack or through symptoms which would develop later in a hospital. For this reason a large amount of experimental work was [Pg 15] carried out on hydrocyanic acid, particularly by the French. Since this gas has a very low density, it was necessary to mix with it substances which would tend to keep it close to the ground during the attack. Various mixtures, all called “vincennite,” were prepared,—chloroform, arsenic trichloride and stannic chloride being used in varying proportions with the acid. It was some time before it was definitely learned that these mixtures were far from being successful, both from the standpoint of stability and of poisonous properties. While the French actually used these mixtures in constantly decreasing quantities on the field for a long time, they were ultimately abandoned, though not until American chemists had also carried out a large number of tests. However, following the recommendation of the American Gas Service in France in December, 1917, no vincennite was ever manufactured by the United States.

Almost simultaneously with the introduction of the gas wave attacks, in which liquefied gas under pressure was liberated from cylinders, came the use of lachrymatory or tear gases. These, while not very poisonous in the concentrations used, were very effective in incapacitating men through the effects produced upon their eyes. The low concentration required (one part in ten million of some lachrymators is sufficient to make vision impossible without a mask) makes this form of gas warfare very economical as well as very effective. Even if a mask does completely protect against such compounds, their use compels an army to wear the mask indefinitely, with an expenditure of shell far short of that required if the much more deadly gases were used. Thus Fries estimates that one good lachrymatory shell will force wearing the mask over an area that would require 500 to 1000 phosgene shell of equal size to produce the same effect. While the number of actual casualties will be very much lower, the total effect considered from the standpoint of the expenditure of ammunition and of the objectives gained, will be just as valuable. So great is the harassing value of [Pg 16] tear and irritant gases that the next war will see them used in quantities approximating that of the more poisonous gases.

The first lachrymator used was a mixture of the chlorides and bromides of toluene. Benzyl chloride and bromide are the only valuable substances in this mixture, the higher halogenated products having little or no lachrymatory value. Xylyl bromide is also effective. Chloroacetone and bromoacetone are also well known lachrymators, though they are expensive to manufacture and are none too stable. Because of this the French modified their preparation and obtained mixtures to which they gave the name “martonite.” This is a mixture of 80 per cent bromoacetone and 20 per cent chloroacetone, and can be made with nearly complete utilization of the halogen. Methyl ethyl ketone may also be used, which gives rise to the “homomartonite” of the French. During the early part of the War, when bromine was so very expensive, the English developed ethyl iodoacetate. This was used with or without the addition of alcohol. Later the French developed bromobenzyl cyanide, C₆H₅CH(Br)CN. This was probably the best lachrymator developed during the War and put into large scale manufacture, though very little of it was available on the field of battle before the War ended. Chloroacetophenone would have played an important part had the War continued.

As will be discussed more fully in the chapters on “The Tactics of Gas,” the wave attacks became relatively less important in 1916 through the use of gas in artillery shell. This was the result of many factors. Cloud gas attacks, as carried out under the old conditions, required a long time for the preliminary preparations, entailed a great deal of labor under the most difficult conditions, and were dangerous of execution even when weather conditions became suitable. The difficulties may be summarized as follows:

(1) The heavy gas cylinders used required a great deal of transportation, and not only took the time of the Infantry but rendered [Pg 17] surprise attacks difficult owing both to the time required and to the unusual activity behind the lines that became, with the development of aeroplanes, more and more readily discerned.

(2) Few gases were available for wave attacks—chlorine, phosgene and, to a less extent, chloropicrin proving to be the only ones successfully used by either the Allies or the Germans. Hydrogen sulfide, carbon monoxide and hydrocyanic acid gas were suggested and tried, but were abandoned for one reason or another.

(3) Gas cloud attacks were wholly dependent upon weather conditions. Not only were the velocity and direction of the wind highly important as regards the successful carrying of the wave over the enemy’s line, but also to prevent danger to the troops making the attack due to a possible shift of the wind, which would carry the gas back over their own line.

(4) The use of gas in artillery shell does not require especially trained troops inasmuch as gas shell are fired in the same manner as ordinary shell, and by the same gun crews. Moreover, since artillery gas shell are used generally only for ranges of a mile or more, the direction and velocity of the wind are of minor importance. Another factor which adds to the advantage of artillery shell in certain cases is the ability to land high concentrations of gas suddenly upon a distant target through employing a large number of the largest caliber guns available for firing gas.

Notwithstanding the above named disadvantages of wave attacks it was felt by the Americans from the beginning that successful gas cloud attacks were so fruitful in producing casualties and were such a strain upon those opposed to it, that they would continue. Furthermore, since artillery shell contain about 10 per cent gas, while gas cylinders may contain 50 per cent, or even more of the total weight of the cylinder, the efficiency of a cloud gas attack for at least the first mile of the enemy’s territory is far greater than that of the artillery gas attack. It was accordingly felt that the only thing necessary to make cloud gas attacks highly useful and of frequent occurrence in the future was the development of mobile methods—methods whereby the gas attack could be [Pg 18] launched on the surface of the ground and at short notice. For these reasons gas wave attacks may be expected to continue and to eventually reach a place of very decided importance in Chemical Warfare.

The firing of gas in artillery shell and in bombs has another great advantage over the wave attack just mentioned. There is a very great latitude in the choice of those gases which have a high boiling point or which, at ordinary temperatures, are solids. Mustard gas is an example of a liquid with a high boiling point, and diphenylchloroarsine an example of a gas that is ordinarily solid. For the above reason the term “gas warfare” was almost a misnomer at the close of the War, and today is true only in the sense that all the substances used are in a gaseous or finely divided condition immediately after the shell explode or at least when they reach the enemy.

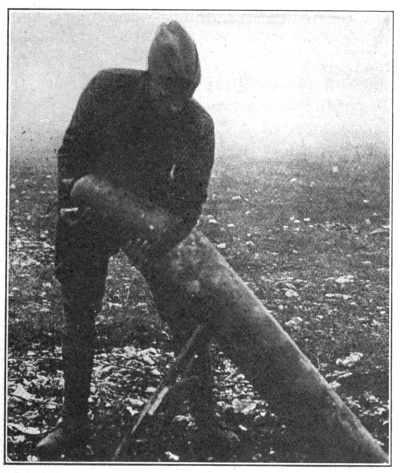

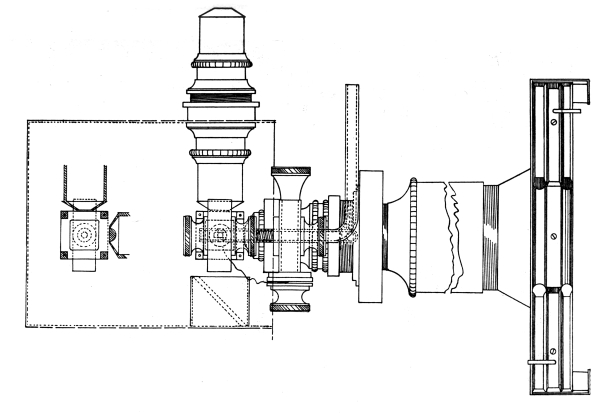

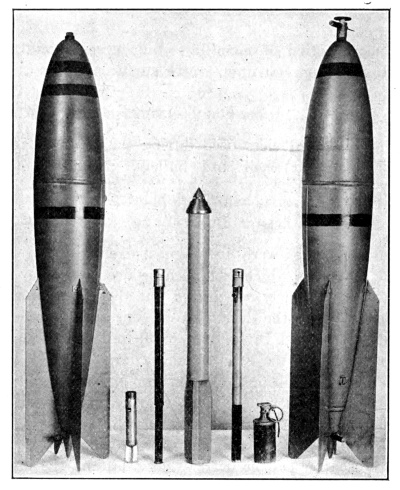

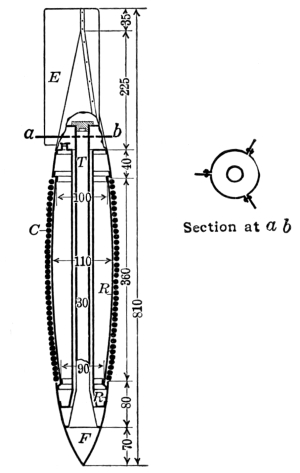

Still another method of attack, developed by the British and first used by them in July, 1917, was the projector (invented by Captain Livens). This was used very successfully up to the close of the War, and though the German attempted to duplicate it, his results were never as effective. The projector consists of a steel tube of uniform cross section, with an internal diameter of about 8 inches. By using nickel steel the weight may be decreased until it is a one man load. The projector was set against a pressed steel base plate (about 16 inches in diameter) placed in a very shallow trench. [Pg 19]

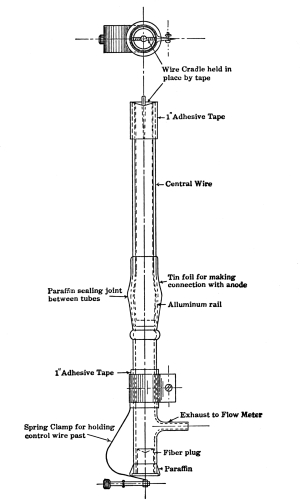

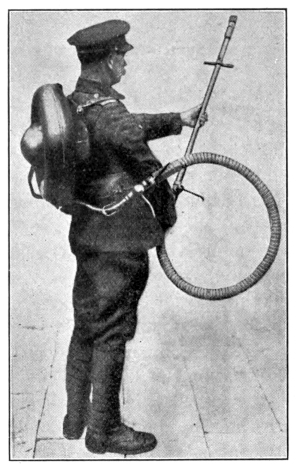

Fig. 2.—Livens’ Projector.

The Type shown is an 18 cm. German Gas Projector,

captured during the 2d Battle of the Marne.

Until about the close of the war projectors were installed by digging a triangular trench deep enough to bring the muzzles of the projectors nearly level with the surface of the ground. They were then protected by sand bags or canvas covers, or camouflaged with wire netting to which colored bits of cloth were tied to simulate leaves and shadows. The projectors were fired by connecting them in series with ordinary blasting machines operated by hand from a convenient point in the rear. The digging in of the projectors in No Man’s Land or very close to it was a dangerous and laborious undertaking. The Americans early conceived the idea that projectors could be fired just as accurately by digging a shallow trench just deep enough to form a support for the base plate, and then supporting the outer ends of the projector on crossed sticks or a light frame work of boards. This idea proved entirely practical except for one condition. It was found necessary to fire with a single battery all the projectors near enough together to be disturbed by the blast from any portion of them. Inasmuch as most of the blasting machines used for firing had a capacity of only 20 to 30 projectors, it was necessary to so greatly scatter a large projector [Pg 20] attack that the method was very little used. However, investigations were well under way at the close of the War to develop portable firing batteries that would enable the discharge of at least 100 and preferably 500 projectors at one time. By this arrangement a projector attack could be prepared and launched in two to four hours, depending upon the number of men available. This enabled the attack to be decided upon in the evening (if the weather conditions were right), and to have the attack launched before morning, thereby making it impossible for aeroplane observers, armed with cameras, to discover the preparation for the projector attack. Since the bombs used in the projector may carry as high as 30 pounds of gas (usually phosgene), some idea of the amount of destruction may be gained when it is known that the British fired nearly 2500 at one time into Lens.

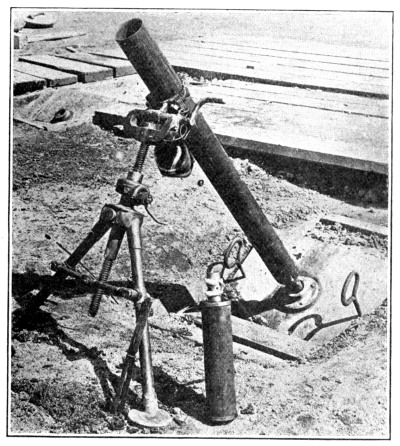

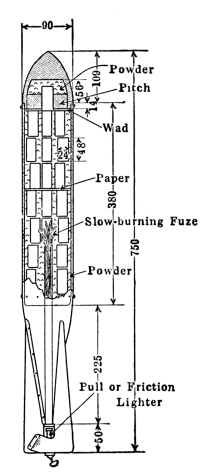

Another British invention is the Stokes’ gun or trench mortar. The range of this gun is about 800 to 1000 yards. It is therefore effective only where the front lines are relatively close together. The shell consists of a case containing the high explosive, smoke material or gas, fitted to a base filled with a high charge of propelling powder. The shell is simply dropped into the gun. At the bottom of the gun there is a projection or stud that strikes the primer, setting off the small charge and expelling the projectile. In order to obtain any considerable concentration of gas in a particular locality, it is necessary to fire the Stokes’ continuously (15 shots per minute being possible under battle conditions) for two to five minutes since the bomb contains only seven pounds of gas.

It is believed that the first gas shell contained lachrymators or tear gases. Although the use of these shell continued up to and even after the introduction of mustard gas, they gradually fell off in number—the true poison gas shell taking their place. Towards the end of 1915 Auld [Pg 21] states that the Germans were using chloromethyl chloroformate (palite) in shell. In 1916, during the battle of the Somme, palite was replaced by superpalite (trichloromethyl chloroformate, or diphosgene) which is more toxic than palite, and about as toxic as phosgene. It has the advantage over phosgene of being much more persistent. In spite of the fact that American chemists were not able to manufacture superpalite on a large scale, or at least so successfully that it would compete in price with other war gases, the Germans used large quantities of it, alone and mixed with chloropicrin, in shell of every caliber up to and including the 15 cm. Howitzer.

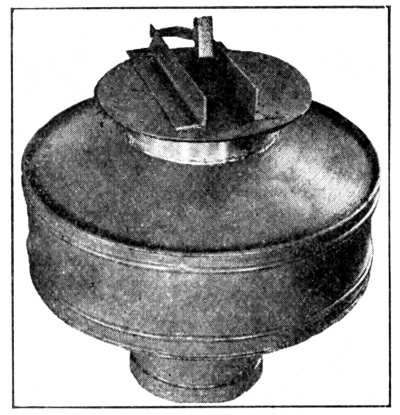

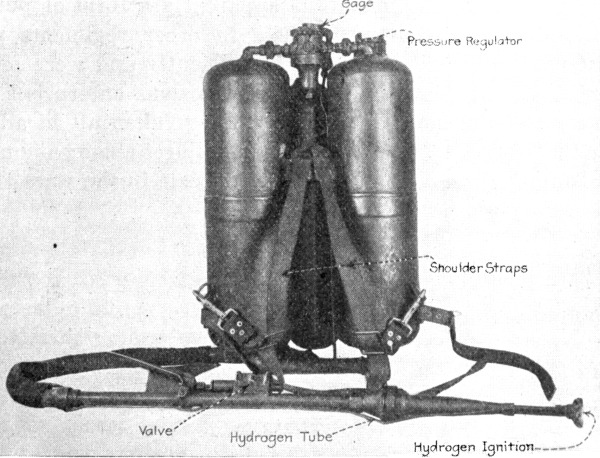

Fig. 3.—Stokes’ Mortar.

The next gas to be introduced was chloropicrin, trichloronitromethane or “vomiting gas.” It has been stated that a mixture of chloropicrin [Pg 22] (25 per cent) and chlorine (75 per cent) has been used in cloud attacks, but the high boiling point of chloropicrin (112° C.) makes its considerable use for this purpose very unlikely. The gas is moderately toxic and somewhat lachrymatory, but it was mainly used because of its peculiar property of causing vomiting when inhaled. Its value was further increased at first because it was particularly difficult to prepare a charcoal which would absorb it. Its peculiar properties are apt to cause it to be used for a long time.

During the summer of 1917 two new and very important gases were introduced, and, as before, by the Germans. One of these was diphenylchloroarsine, “sneezing gas” or “Blue Cross.” This is a white solid which was placed in a bottle and embedded in TNT in the shell. Upon explosion of the shell the solid was atomized into very fine particles. Since the ordinary mask does not remove smoke or mists, the sneezing gas penetrates the mask and causes violent sneezing. The purpose, of course, is to compel the removal of the mask in an atmosphere of lethal gas. (The firing regulations prescribed its use with phosgene or other lethal shell.) The latest type masks protect against this dust, but as it is extraordinarily powerful, its use will continue.

The second gas was dichloroethyl sulfide, mustard gas, Yellow Cross or Yperite. Mustard gas, as it is commonly designated, is probably the most important single poisonous substance used in gas warfare. It was first used by the Germans at Ypres, July 12, 1917. The amount of this gas used is illustrated by the fact that at Nieuport more than 50,000 shell were fired in one night, some of which contained nearly three gallons of the liquid.

Mustard gas is a high boiling and very persistent material, which is characterized by its vesicant (skin blistering) action. Men who come in contact with it, either in the form of fine splashes of the liquid or in the form of vapor, suffer severe blistering of the skin. The burns appear from four to twelve hours after exposure and heal very slowly. [Pg 23] Ordinary clothing is no protection against either the vapor or the liquid. Other effects will be considered in Chapter IX.

Since then there has been no important advance so far as new gases are concerned. Various arsenic derivatives were prepared in the laboratory and tested on a small scale. The Germans did actually introduce ethyldichloroarsine and the Americans were considering methyldichloroarsine. Attempts were made to improve upon mustard gas but they were not successful.

It is rather a peculiar fact that so few new chemical compounds were used as war gases. Practically all the substances were well known to the organic chemist long before the World War. One of the most interesting and valuable of the compounds which would have found extensive use had the War continued, is an arsenic compound called Lewisite from its discoverer, Capt. W. Lee Lewis, of Northwestern University. The chemistry of this compound is discussed in Chapter X. Because of the early recognized value of this compound, very careful secrecy was maintained as to all details of the method of preparation and its properties. As a result, strange stories were circulated about its deadly powers. Characteristic of these was the story that appeared in the New York Times early in 1919. Now that the English have published the chemical and pharmacological properties, we can say that, although Lewisite was never proven on the battle field, laboratory tests indicate that we have here a very powerful agent. Not only is it a vesicant of about the same order of mustard gas, but the arsenical penetrates the skin of an animal, and three drops, placed on the abdomen of a mouse, are sufficient to kill within two to three hours. It is also a powerful respiratory irritant and causes violent sneezing. Its possible use in aeroplane bombs has led General Fries to apply the term “The Dew of Death” to its use in this way.

Considerable effort was spent on the question of camouflage gases. This involved two lines of research:

(1) To prevent the recognition of a gas when actually present on the field, by masking its odor. [Pg 24]

TABLE I

Chemical Warfare Gases

| Chemical | Belligerent | Effect | Means of Projection |

|---|---|---|---|

| Acrolein (allylaldehyde) | French | Lachrymatory | Hand grenades |

| Lethal | |||

| Arsenic chloride | (In mixtures. See below) | ||

| Benzyl iodide | French | Lachrymatory | Artillery shell |

| Benzyl chloride | French | Lachrymatory | Artillery shell |

| Bromoacetone | French | Lachrymatory | Artillery shell |

| Lethal | |||

| Bromobenzylcyanide | French | Lachrymatory | Artillery shell |

| Bromomethylethylketone | German | Lachrymatory | Artillery shell |

| Lethal | Artillery shell | ||

| Benzyl bromide | German | Lachrymatory | Artillery shell |

| French | |||

| Chlorine | German | Lethal | Cylinders |

| British | (cloud gas) | ||

| French | |||

| American | |||

| Chlorosulfonic acid | German | Irritant | Hand grenades, |

| light minenwerfer | |||

| Chloroacetone | French | Lachrymatory | Artillery shell |

| Chlorobenzene (as solvent) | German | Lachrymatory | Artillery shell |

| Chloropicrin | British | Lethal | Artillery shell |

| French | Lachrymatory | Trench mortar bombs | |

| German | Projectors | ||

| American | [Pg 25] | ||

| Cyanogen bromide | Austrian | Lethal | Artillery shell |

| Dichloromethylether | German | Lachrymatory | Artillery shell |

| (as solvent) | |||

| Diphenylchloroarsine | German | Sternutatory | Artillery shell |

| Lethal | |||

| Dichloroethylsulfide | German | Vesicant | Artillery shell |

| French | Lethal | ||

| British | Irritant | ||

| American | |||

| Ethyldichloroarsine | German | Lethal | Artillery shell |

| Ethyliodoacetate | British | Lachrymatory | Artillery shell, |

| 4-in. Stokes’ mortars, | |||

| hand grenades | |||

| Hydrocyanic acid | French | (In mixtures. See below) | Lachrymatory |

| Methylchlorosulfonate | German | Irritant | Minenwerfer |

| Monochloromethylchloroformate | French | Lachrymatory | Lachrymatory |

| Phosgene | British | Lethal | Projectors, |

| French | trench mortars, | ||

| German | artillery shell, | ||

| American | cylinders | ||

| Phenylcarbylaminechloride | German | Lachrymatory | Artillery shell |

| Irritant | |||

| Trichlormethylchloroformate | German | Lethal | Artillery shell |

| Stannic chloride | British | Irritant | Hand grenades |

| French | Cloud forming | Artillery | |

| American | Projectors | ||

| 4-in. Stokes’ | |||

| mortar bombs | |||

| Sulfuric anhydride | German | Irritant | Hand grenades, |

| minenwerfer, | |||

| artillery shell | |||

| Xylyl bromide | German | Lachrymatory | Artillery shell |

[Pg 26]

TABLE I—Continued

| Chemical | Belligerent | Effect | Means of Projection |

|---|---|---|---|

| Mixtures[4] | |||

| Bromoacetone (80%) and | French | Lachrymatory | Artillery shell |

| Chloroacetone (20%) | Lethal | ||

| Chlorine (50%) and | British | Lethal | Cylinders |

| Phosgene (50%) | German | ||

| Chlorine (70%) and | British | Lethal | Cylinders |

| Chloropicrin (30%) | Lachrymatory | ||

| Chloropicrin (65%) and | British | Lethal | Cylinders |

| Hydrogen sulfide (35%) | Lachrymatory | ||

| Chloropicrin (80%) and | British | Lethal | Artillery shell |

| Stannic chloride (20%) | French | Lachrymatory | Trench mortar bombs |

| American | Irritant | Projectors | |

| Chloropicrin (75%) and | Lethal | Artillery shell | |

| Phosgene (25%) | British | Lachrymatory | Trench mortar bombs, |

| projectors | |||

| Dichloroethyl sulfide (80%) | German | Vesicant | |

| and Chlorobenzene (20%) | French | Lethal | Artillery shell |

| British | |||

| American | |||

| Ethyl carbazol (50%) and | German | Sternutatory | Artillery shell |

| Diphenylcyanoarsine (50%) | Lethal [Pg 27] | ||

| Ethyldichloroarsine (80%) and | German | Lethal | Artillery shell |

| Dichloromethylether (20%) | Lachrymatory | ||

| Ethyliodoacetate (75%) and | Artillery shell, | ||

| Alcohol (25%) | British | Lachrymatory | 4-in. Stokes’ mortars, |

| hand grenades | |||

| Hydrocyanic acid (55%) | British | Lethal | Artillery shell |

| Chloroform (25%) and | |||

| Arsenious chloride (20%) | |||

| Hydrocyanic acid (50%), | |||

| Arsenious chloride (30%), | French | Lethal | Artillery shell |

| Stannic chloride (15%) and | |||

| Chloroform (5%) | |||

| Phosgene (50%) and | British | Lethal | Artillery shell |

| Arsenious chloride (50%) | |||

| Dichloroethyl sulfide (80%) | German | Vesicant | |

| and Carbon tetrachloride (20%) | French | Lethal | Artillery shell |

| British | |||

| American | |||

| Phosgene (60%) and | British | Lethal | Artillery shell |

| Stannic chloride (40%) | French | Irritant | |

| Methyl sulfate (75%) and | French | Lachrymatory | Artillery shell |

| Chloromethyl sulfate (25%) | Irritant |

[Pg 28] (2) To simulate the presence of a toxic gas. This may be done either by using a substance whose odor in the field strongly suggests that of the gas in question, or by so thoroughly associating a totally different odor with a particular “gas” in normal use that, when used alone, it still seems to imply the presence of that gas. This use of imitation gas would thus be of service in economizing the use of actual “gas” or in the preparation of surprise attacks.

While there was some success with this kind of “gas,” very few such attacks were really carried out, and these were in connection with projector attacks.

Table I gives a list of all the gases used by the various armies, the nation which used them, the effect produced and the means of projection used.

Table II gives the properties of the more important war cases (compiled by Major R. E. Wilson, C. W. S.).

The gases used by the Germans may also be classified by the names of the shell in which they were used. Table III gives such a classification.

In selecting markings for American chemical shell, red bands were used to denote persistency, white bands to denote non-persistency and lethal properties, yellow bands to denote smoke, and purple bands to denote incendiary action. The number of bands indicates the relative strength of the property indicated; thus, three red bands denote a gas more persistent than one red band.

The following shell markings were actually used:

| 1 White | Diphenylchloroarsine |

| 2 White | Phosgene |

| 1 White, 1 red | Chloropicrin |

| 1 White, 1 red, 1 white | 75% Chloropicrin, 25% Phosgene |

| 1 White, 1 red, 1 yellow | 80% Chloropicrin, 20% Stannic Chloride |

| 1 Red | Bromoacetone |

| 2 Red | Bromobenzylcyanide |

| 3 Red | Mustard Gas |

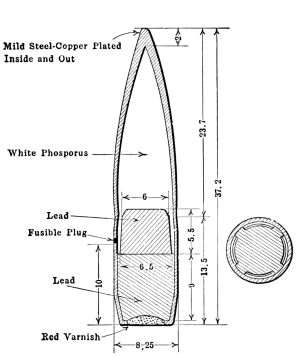

| 1 Yellow | White Phosphorus |

| 2 Yellow | Titanium Tetrachloride |

[Pg 29]

TABLE II

Physical Constants of Important War Gases

| Name of Gas | Formula | Molecular Weight |

Liquid Density at 20° C. under Own Pressure |

Melting point, °C. |

Boiling point, °C. |

Vapor Pressure at 20° C. (mm. Hg) |

|---|---|---|---|---|---|---|

| Bromoacetone | C₃H₅BrO | 136.98 | 1.7(?) | - 54 | 126 | 9(?) |

| Carbon monoxide | CO | 28.00 | (Gas) | -207 | -190 | (Gas) |

| Cyanogen bromide | BrCN | 106.02 | 2.01 | 52 | 61.3 | 89 |

| Cyanogen chloride | ClCN | 61.56 | 1.186 | - 6 | 15 | 1002 |

| Chlorine | Cl₂ | 70.92 | 1.408 | -101.5 | 33.6 | 5126 |

| Chloropicrin | Cl₃C(NO₂) | 164.39 | 1.654 | - 69.2 | 112 | 18.9 |

| Dichloroethyl sulfide | (CH₃CHCl₂)S | 169.06 | 1.274 | 12.5 | 216 | .06 |

| Diphenylchloroarsine | (C₆H₅)₂AsCl | 264.56 | 1.422 | 44 | 333 | .0025 |

| Hydrocyanic acid | HCN | 27.11 | .697 | - 14 | 26.1 | 603 |

| Phenyldichloroarsine | C₆H₅AsCl₂ | 210.96 | 1.640 | ... | 253 | .022 |

| Phosgene | COCl₂ | 98.92 | 1.38 | ... | 8.2 | 1215 |

| Stannic chloride | SnCl₄ | 260.54 | 2.226 | - 33 | 114 | 18.58 |

| Superpalite | CCl₃COOCl | 197.85 | 1.65 | ... | 128 | 10.3 |

| Xylyl bromide | ( CH₃)C₆H₄CH₂Br | 185.03 | 1.381 | - 2 | 214.5 | ... |

[Pg 30]

TABLE III

German Shell

| Name of Shell | Shell Filling | Nature of Effect |

|---|---|---|

| B-shell [K₁ shell (White B or BM)] | Bromoketone | Lachrymator |

| (Bromomethylethyl ketone) | ||

| Blue Cross | (a) Diphenylchloroarsine | Sternutator |

| (b) Diphenylcyanoarsine | Sternutator | |

| (c) Diphenylchloroarsine, | ||

| Ethyl carbazol | ||

| C-shell (Green Cross) (White C) | Superpalite | Asphyxiant |

| D-shell (White D) | Phosgene | Lethal |

| Green Cross | (a) Superpalite | Asphyxiant |

| (b) Phenylcarbylaminechloride | ||

| Green Cross 1 | Superpalite 65%, | Asphyxiant |

| Chloropicrin 35% | ||

| Superpalite, | ||

| Green Cross 2 | Phosgene, | Asphyxiant |

| Diphenylchloroarsine | ||

| Green Cross 3 | Ethyldichloroarsine, | |

| (Yellow Cross 1) | Methyldibromoarsine, | Asphyxiant |

| Dichloromethyl ether | ||

| K-shell (Yellow) | Chloromethylchloroformate | Asphyxiant |

| (Palite) | ||

| T-shell (Black or green T) | Xylyl bromide, | Lachrymator |

| Bromo ketone | ||

| Yellow Cross | Mustard gas, | Vesicant |

| Diluent (CCl₄, C₆H₅Cl, C₆H₅NO₂) | ||

| Yellow Cross 1 | See Green Cross 3 |

[Pg 31]

Modern chemical warfare dates from April 22, 1915. Really, however, it may be said to have started somewhat earlier, for Germany undoubtedly had spent several months in perfecting a successful gas cylinder and a method of attack. The Allies, surprised by such a method of warfare, were forced to develop, under pressure, a method of defense, and then, when it was finally decided to retaliate, a method of gas warfare. “Offensive organizations were enrolled in the Engineer Corps of the two armies and trained for the purpose of using poisonous gases; the first operation of this kind was carried out by the British at the battle of Loos in September, 1915.

“Shortly after this the British Army in the field amalgamated all the offensive, defensive, advisory and supply activities connected with gas warfare and formed a ‘Gas Service’ with a Brigadier General as Director. This step was taken almost as a matter of necessity, and because of the continually increasing importance of the use of gas in the war (Auld).”

At once the accumulation of valuable information and experience was started. Later this was very willingly and freely placed at the disposal of American workers. Too much cannot be said about the hearty co-operation of England and France. Without it and the later exchange of information on all matters regarding gas warfare, the progress of gas research in all the allied countries would have been very much retarded.

While many branches of the American Army were engaged in following the progress of the war during 1915-1916, the growing importance of gas warfare was far from being appreciated. When the United States declared war on Germany April 6, 1917, there were a few scattered observations [Pg 32] on gas warfare in various offices of the different branches, but there was no attempt at an organized survey of the field, while absolutely no effort had been made by the War Department to inaugurate research in a field that later had 2,000 men alone in pure research work. Equally important was the fact that no branch of the Service had any idea of the practical methods of gas warfare.

The only man who seemed to have the vision and the courage of his convictions was Van H. Manning, Director of the Bureau of Mines. Since the establishment of the Bureau in 1908 it had maintained a staff of investigators studying poisonous and explosive gases in mines, the use of self-contained breathing apparatus for exploring mines filled with noxious gases, the treatment of men overcome by gas, and similar problems. At a conference of the Director of the Bureau with his Division Chiefs, on February 7, 1917, the matter of national preparedness was discussed, and especially the manner in which the Bureau could be of most immediate assistance with its personnel and equipment. On February 8, the Director wrote C. D. Walcott, Chairman of the Military Committee of the National Research Council, pointing out that the Bureau of Mines could immediately assist the Navy and the Army in developing, for naval or military use, special oxygen breathing apparatus similar to that used in mining. He also stated that the Bureau could be of aid in testing types of gas masks used on the fighting lines, and had available testing galleries at the Pittsburgh experiment station and an experienced staff. Dr. Walcott replied on February 12 that he was bringing the matter to the attention of the Military Committee.

A meeting was arranged between the Bureau and the War College, the latter organization being represented by Brigadier General Kuhn and Major L. P. Williamson. At this conference the War Department enthusiastically accepted the offer of the Bureau of Mines and agreed to support the work in every way possible.

The supervision of the research on gases was offered to Dr. G. A. Burrell, for a number of years in charge of the chemical work done by the Bureau in connection with the investigation of mine gases and [Pg 33] natural gas. He accepted the offer on April 7, 1917. The smoothness with which the work progressed under his direction and the importance of the results obtained were the result of Colonel Burrell’s great tact, his knowledge of every branch of research under investigation and his imagination and general broad-mindedness.

Once, however, that the importance of gas warfare had been brought to the attention of the chemists of the country, the response was very eager and soon many of the best men of the university and industrial plants were associated with Burrell in all the phases of gas research. The staff grew very rapidly and laboratories were started at various points in the East and Middle West.

It was immediately evident that there should be a central laboratory in Washington to co-ordinate the various activities and also to considerably enlarge those activities under the joint direction of the Army, the Navy and the Bureau of Mines. Fortunately a site was available for such a laboratory at the American University, the use of the buildings and grounds having been tendered President Wilson on April 30, 1917. Thus originated the American University Experiment Station, later to become the Research Division of the Chemical Warfare Service.

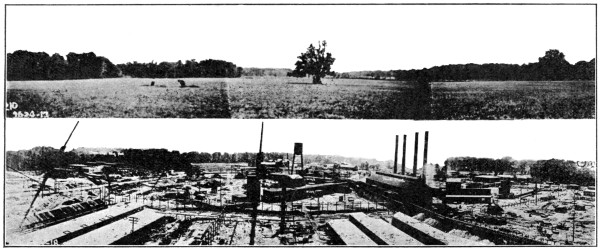

Meanwhile other organizations were getting under way. The procurement of toxic gases and the filling of shell was assigned to the Trench Warfare Section of the Ordnance Department. In June, 1917, General Crozier, then Chief of the Ordnance Department, approved the general proposition of building a suitable plant for filling shell with toxic gas. In November, 1917, it was decided to establish such a plant at Gunpowder Neck, Maryland. Owing to the inability of the chemical manufacturers to supply the necessary toxic gases, it was further decided, in December, 1917, to erect at the same place such chemical plants as would be necessary to supply these gases. In January, 1918, the name was changed to Edgewood Arsenal, and the project was made a separate Bureau of the Ordnance Department, Col. William H. Walker, of the Massachusetts Institute of Technology, being soon afterwards put in command. [Pg 34]

While, during the latter part of the War, gas shell were handled by the regular artillery, special troops were needed for cylinder attacks, Stokes’ mortars, Livens’ projectors and for other forms of gas warfare. General Pershing early cabled, asking for the organization and training of such troops, and recommended that they be placed, as in the English Army, under the jurisdiction of the Engineer Corps. On August 15, 1917, the General Staff authorized one regiment of Gas and Flame troops, which was designated the “30th Engineers,” and was commanded by Major (later Colonel) E. J. Atkisson. This later became the First Gas Regiment, of the Chemical Warfare Service.

About this time (September, 1917) the need of gas training was recognized by the organization of a Field Training Section, under the direction of the Sanitary Corps, Medical Department. Later it was recognized that neither the Training Section nor the Divisional Gas Officers should be under the Medical Department, and, in January, 1918, the organization was transferred to the Engineer Corps.

All of these, with the exception of the Gas and Flame regiment, were for service on this side. The need for an Overseas force was recognized and definitely stated in a letter, dated August 4, 1917. On September 3, 1917, an order was issued establishing the Gas Service, under the command of Lt. Col. (later Brigadier General) A. A. Fries, as a separate Department of the A. E. F. in France. In spite of a cable on September 26th, in which General Pershing had said

“Send at once chemical laboratory, complete equipment and personnel, including physiological and pathological sections, for extensive investigation of gases and powders....”

it was not until the first of January, 1918, that Colonel R. F. Bacon of the Mellon Institute sailed for France with about fifty men and a complete laboratory equipment.

Meantime a Chemical Service Section had been organized in the United States. This holds the distinction of being the first recognition of chemistry as a separate branch of the military service in any country or any war. This was authorized October 16, 1917, and was to consist of an officer of the Engineers, not above the rank of colonel, who was to be Director of Gas Service, with assistants, not above the rank of [Pg 35] lieutenant colonel from the Ordnance Department, Medical Department and Chemical Service Section. The Section itself was to consist of 47 commissioned and 95 non-commissioned officers and privates. Colonel C. L. Potter, Corps of Engineers, was appointed Director and Professor W. H. Walker was commissioned Lieutenant Colonel and made Assistant Director of the Gas Service and Chief of the Chemical Service Section. This was increased on Feb. 15, 1918 to 227 commissioned and 625 enlisted men, and on May 6, 1918 to 393 commissioned and 920 enlisted men. Meanwhile Lt. Col. Walker had been transferred to the Ordnance and Lt. Col. Bogert had been appointed in his place.

At this time practically every branch of the Army had some connection with Gas Warfare. The Medical Corps directed the Gas Defense production. Offense production was in the hands of the Ordnance Department. Alarm devices, etc., were made by the Signal Corps. The Engineers contributed their 30th Regiment (Gas and Flame) and the Field Training Section. The Research Section was still in charge of the Bureau of Mines, in spite of repeated attempts to militarize it. And in addition, the Chemical Service Section had been formed primarily to deal with overseas work. While the Director of the Gas Service was expected to co-ordinate all these activities, he was given no authority to control policy, research or production.

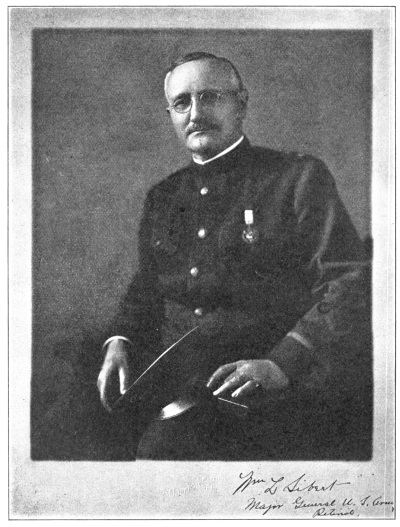

In order to improve these conditions Major General Wm. L. Sibert, a distinguished Engineer Officer who built the Gatun Locks and Dam of the Panama Canal and who had commanded the First Division in France, was appointed Director of the Chemical Warfare Service on May 11, 1918. Under his direction the Chemical Warfare Service was organized with the following Divisions:

| Overseas | Brigadier General Amos A. Fries |

| Research | Colonel G. A. Burrell |

| Development | Colonel F. M. Dorsey |

| Gas Defense Production | Colonel Bradley Dewey |

| Gas Offense Production | Colonel Wm. H. Walker |

| Medical | Colonel W. J. Lyster |

| Proving | Lt. Col. W. S. Bacon |

| Administration | Brigadier General H. C. Newcomer |

| Gas and Flame | Colonel E. J. Atkisson |

[Pg 36] The final personnel authorized, though never reached owing to the signing of the Armistice, was 4,066 commissioned officers and 44,615 enlisted men; this was including three gas regiments of eighteen companies each.

General Sibert brought with him not only an extended experience in organizing and conducting big business, but a strong sympathy for the work and an appreciation of the problem that the American Army was facing in France. He very quickly welded the great organization of the Chemical Warfare Service into a whole, and saw to it that each department not only carried on its own duties but co-operated with the others in carrying out the larger program, which, had the war continued, would have beaten the German at his own game.

More detailed accounts will now be given of the various Divisions of the Chemical Warfare Service.

The Administration Division was the result of the development which has been sketched in the preceding pages. It is not necessary to review that, but the organization as of October 19, 1918 will be given:

| Director | Major General Wm. L. Sibert |

| Staff: | |

| Medical Officer | Colonel W. J. Lyster |

| Ordnance Officer | Lt. Col. C. B. Thummel |

| British Military Mission | Major J. H. Brightman |

| Assistant Director | Colonel H. C. Newcomer |

| Office Administration | Major W. W. Parker |

| Relations Section | Colonel M. T. Bogert |

| Personnel Section | Major F. E. Breithut |

| Contracts and Patents Section | Captain W. K. Jackson |

| Finance Section | Major C. C. Coombs |

| Requirements and Progress Section | Capt. S. M. Cadwell |

| Confidential Information Section | Major S. P. Mullikin |

| Transportation Section | Captain H. B. Sharkey |

| Training Section | Lt. Col. G. N. Lewis |

| Procurement Section | Lt. Col. W. J. Noonan |

The administrative offices were located in the Medical Department Building. The function of most of the sections is indicated by their names. [Pg 37]

The Industrial Relations Section was created to care for the interests of the industrial plants which were considered as essential war industries. Through its activity many vitally important industries were enabled to retain, on deferred classification or on indefinite furlough, those skilled chemists without which they could not have maintained a maximum output of war munitions.

In the same way the University Relations Section cared for the educational and research institutions. In this way our recruiting stations for chemists were kept in as active operation as war conditions permitted.

Another important achievement of the Administration Section was to secure the order from The Adjutant General, dated May 28, 1918, that read:

“Owing to the needs of the military service for a great many men trained in chemistry, it is considered most important that all enlisted men who are graduate chemists should be assigned to duty where their special knowledge and training can be fully utilized.

“Enlisted men who are graduate chemists will not be sent overseas unless they are to be employed on chemical duties....”

While this undoubtedly created a great deal of feeling among the men who naturally were anxious to see actual fighting in France, it was very important that this order be carried out in order to conserve our chemical strength. The following clipping from the September, 1918, issue of The Journal of Industrial and Engineering Chemistry shows the result of this order.

“Chemists in Camp

“As the result of the letter from The Adjutant General of the Army, dated May 28, 1918, 1,749 chemists have been reported on. Of these the report of action to August 1, 1918, shows that 281 were ordered to remain with their military organization because they were already performing chemical duties, 34 were requested to remain with their military organization because they were more useful in the military work which they were doing, 12 were furloughed back to industry, 165 [Pg 38] were not chemists in the true sense of the word and were, therefore, ordered back to the line, and 1,294 now placed in actual chemical work. There were being held for further investigation of their qualifications on August 1, 1918, 432 men. The remaining 23 men were unavailable for transfer, because they had already received their overseas orders.

“The 1,294 men, who would otherwise be serving in a purely military capacity and whose chemical training is now being utilized in chemical work, have, therefore, been saved from waste.

“Each case has been considered individually, the man’s qualifications and experience have been studied with care, the needs of the Government plants and bureaus have been considered with equal care, and each man has been assigned to the position for which his training and qualifications seem to fit him best.

“Undoubtedly, there have been some cases in which square pegs have been fitted into round holes, but, on the whole, it is felt that the adjustments have been as well as could be expected under the circumstances.”

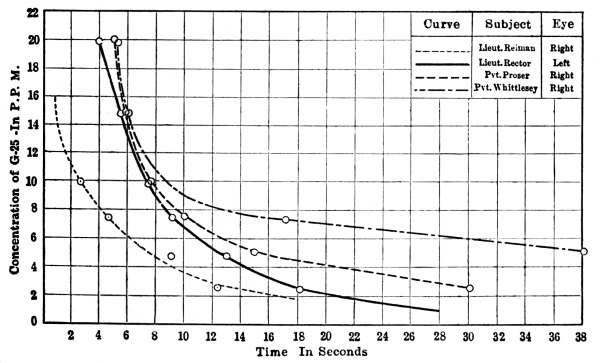

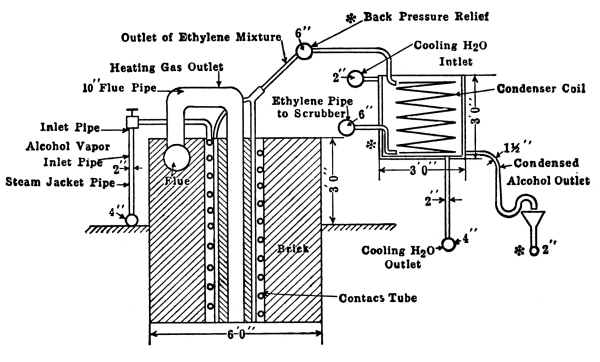

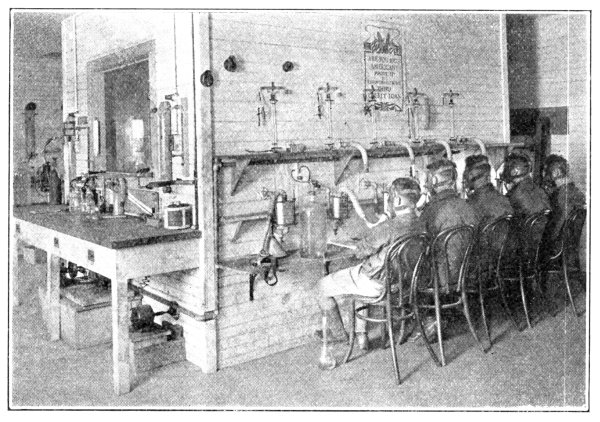

The American University Experiment Station, established by the Bureau of Mines in April, 1917, became July 1, 1918 the Research Division of the Chemical Warfare Service. For the first five months work was carried out in various laboratories, scattered over the country. In September, 1917, the buildings of the American University became available; a little later portions of the new chemical laboratory of the Catholic University, Washington, were taken over. Branch laboratories were established in many of the laboratories of the Universities and industrial plants, of which Johns Hopkins, Princeton, Yale, Ohio State, Massachusetts Institute of Technology, Harvard, Michigan, Columbia, Cornell, Wisconsin, Clark, Bryn Mawr, Nela Park and the National Carbon Company were active all through the war.